Quick-reference guide: Know your knife steels

7th Aug 2015

The products in the KnivesShipFree inventory represent dozens of different steels -- stainless steels and carbon steels, tool steels and "super" steels -- and we know that can be a bit overwhelming when all you're trying to do is choose a knife. That's why we put together this handy quick-reference guide, arranged in alpha-numerical order.

3G

What it is: 3G is a powder-metallurgy stainless steel used by Fällkniven.

Advantages: Wear resistance, corrosion resistance.

Disadvantages: Can be difficult to sharpen.

Who uses it: Fällkniven.

13C26

What it is: 13C26 is a Sandvik stainless steel commonly used in razors and kitchen knives.

Advantages: Toughness, edge retention.

Disadvantages: Modest corrosion resistance.

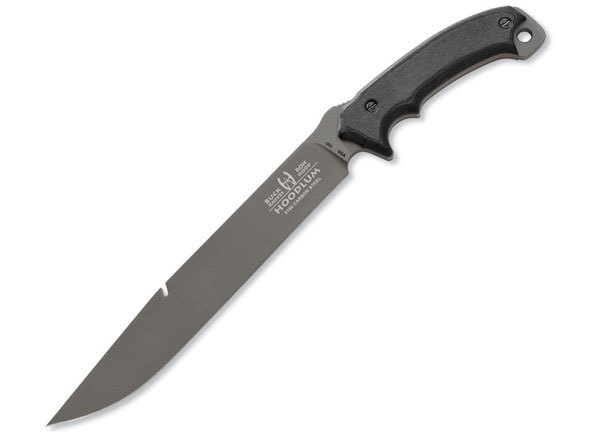

Who uses it: Buck Knives.

14C28N

What it is: 14C28N is a Sandvik stainless steel commonly used in razors and kitchen knives.

Advantages: Toughness, edge retention.

Disadvantages: Modest corrosion resistance.

Who uses it: Kershaw.

19C27

What it is: 19C27 is a Sandvik stainless steel commonly used in heavy-use sporting knives.

Advantages: Edge retention, wear resistance, corrosion resistance.

Disadvantages: Relatively difficult to sharpen.

Who uses it: Canal Street Cutlery.

154 CM

What it is: Crucible 154 CM is a high-quality stainless steel, one of the most popular modern corrosion-resistant steels.

Advantages: Toughness, edge holding, corrosion resistance.

Disadvantages: Can be relatively difficult to sharpen (compared to carbon steels and softer stainless steels).

Who uses it: Benchmade, Emerson Knives, Tuna Valley Cutlery.

420HC

What it is: 420HC is a relatively soft, cost-effective stainless steel.

Advantages: Easy to sharpen, extremely corrosion-resistant (the most corrosion-resistant of the 400-series stainless steels).

Disadvantages: Relatively modest edge-holding.

Who uses it: Great Eastern Cutlery, Kershaw, Schatt & Morgan.

440A

What it is: 440A is a relatively soft, cost-effective stainless steel.

Advantages: Very corrosion-resistant, relatively easy to sharpen.

Disadvantages: Relatively modest edge-holding ability.

Who uses it: Buck Knives.

440C

What it is: 440C is a relatively soft, cost-effective stainless steel.

Advantages: Very corrosion-resistant, relatively easy to sharpen.

Disadvantages: Relatively modest edge-holding.

Who uses it: Benchmade, Canal Street Cutlery, Great Eastern Cutlery.

1084

What it is: 1084 is a plain carbon steel which is popular with forgers.

Advantages: Ease-of-sharpening, edge-holding.

Disadvantages: Rusts relatively easily.

Who uses it: Lon Humphrey Custom Knives.

1095

What it is: 1095 is a plain carbon steel, very common in folding and fixed-blade knives designed for everyday use.

Advantages: Ease-of-sharpening, edge-holding.

Disadvantages: Rusts relatively easily.

Who uses it: Great Eastern Cutlery, Hess Knifeworks, Lon Humphrey Custom Knives, Northwoods Knives.

5160

What it is: 5160, often called "spring steel," is a carbon steel commonly used in large knives.

Advantages: Toughness, wear resistance.

Disadvantages: Rusts relatively easily.

Who uses it: Buck Knives.

A2

What it is: A2 is a carbon tool steel, known for its toughness and ease-of-maintenance.

Advantages: Toughness, ease-of-sharpening.

Disadvantages: Relatively low wear resistance.

Who uses it: Bark River Knives, Fiddleback Forge (handmade), L.T. Wright Handmade Knives.

CPM 3V

What it is: CPM 3V is a "Crucible Particle Metallurgy" carbon tool steel, widely regarded as a "super steel" for its properties and performance.

Advantages: Extraordinary toughness, wear resistance.

Disadvantages: Relatively more difficult to sharpen than predecessor steels like A2.

Who uses it: Bark River Knives, Fiddleback Forge (handmade), Koster Knives.

CPM 4V

What it is: CPM 4V is a "Crucible Particle Metallurgy" carbon tool steel, widely regarded as a "super steel" for its properties and performance.

Advantages: Relative toughness, wear resistance.

Disadvantages: Relatively more difficult to sharpen than CPM 3V and predecessor tool steels like A2, not as tough as CPM 3V.

Who uses it: Bark River Knives.

CPM 20CV

What it is: CPM 20CV is a "Crucible Particle Metallurgy" stainless steel, widely regarded as a "super steel" for its properties and performance.

Advantages: Outstanding edge holding and corrosion resistance, requires little maintenance.

Disadvantages: Very difficult to sharpen.

Who uses it: Bark River Knives.

CPM 154

What it is: CPM 154 is the "Crucible Particle Metallurgy" version of 154 CM stainless steel, and is widely regarded as a "super steel" for its properties and performance.

Advantages: Toughness, edge retention, corrosion resistance.

Disadvantages: Can be relatively difficult to sharpen (compared to carbon steels and softer stainless steels).

Who uses it: Bark River Knives, Fiddleback Forge, Northwoods, Alan Warren.

CPM M4

What it is: CPM M4 is a "Crucible Particle Metallurgy" carbon tool steel, widely regarded as a "super steel" for its properties and performance.

Advantages: Relative toughness, wear resistance.

Disadvantages: Relatively more difficult to sharpen than CPM 3V and predecessor tool steels like A2, not as tough as CPM 3V or CPM 4V.

Who uses it: Bark River Knives, Zero Tolerance.

CPM S30V

What it is: CPM S30V is a "Crucible Particle Metallurgy" stainless steel, widely regarded as a "super steel" for its properties and performance.

Advantages: Wear resistance, corrosion resistance.

Disadvantages: Relatively difficult to sharpen, can be prone to chipping in certain applications.

Who uses it: Benchmade, Buck Knives, Chris Reeve Knives, Kershaw, Spartan Blades, Alan Warren, Zero Tolerance.

CPM S35VN

What it is: CPM S35VN is a "Crucible Particle Metallurgy" stainless steel, an improvement over CPM S30V, and is widely regarded as a "super steel" for its properties and performance.

Advantages: Toughness, wear resistance, corrosion resistance.

Disadvantages: Relatively difficult to sharpen.

Who uses it: Bark River Knives, Arno Bernard Knives, Chris Reeve Knives, Fiddleback Forge (production), Spartan Blades, Three Sisters Forge, Zero Tolerance.

CPM S90V

What it is: CPM S90V is a "Crucible Particle Metallurgy" stainless steel, widely regarded as a "super steel" for its properties and performance.

Advantages: Wear resistance, corrosion resistance.

Disadvantages: Very difficult to sharpen.

Who uses it: Benchmade.

Cru-Wear

What it is: Crucible Cru-Wear is a tool steel with tremendous wear resistance and excellent overall toughness.

Advantages: Toughness, edge retention, wear resistance.

Disadvantages: Can be relatively difficult to sharpen.

Who uses it: Bark River Knives.

D2

What it is: D2 is a carbon tool steel with a relatively high chromium content, prompting some to call it a "semi-stainless" steel. Not as tough as the best carbon steels, it's tougher than most stainless steels.

Advantages: Wear resistance, rust resistance (compared to other carbon steels).

Disadvantages: Relatively more difficult to sharpen than other tool steels.

Who uses it: Benchmade, Canal Street Cutlery, Brous Blades, Queen Cutlery, L.T. Wright Handmade Knives.

Elmax

What it is: Elmax stainless steel, a powder-metallurgy material produced by Bohler-Uddeholm, is widely regarded as a "super steel" for its properties and performance.

Advantages: Toughness, extremely high wear resistance and corrosion resistance.

Disadvantages: Can be difficult to sharpen.

Who uses it: Bark River Knives, LionSteel, Zero Tolerance.

M390

What it is: M390 stainless steel, a powder-metallurgy material produced by Bohler-Uddeholm, is widely regarded as a "super steel" for its properties and performance.

Advantages: Extremely high wear resistance and corrosion resistance.

Disadvantages: Relatively difficult to sharpen.

Who uses it: Benchmade, Zero Tolerance.

N680

What it is: N680 is a stainless steel produced by Bohler-Uddeholm, commonly used where corrosion resistance is important.

Advantages: High corrosion resistance, toughness.

Disadvantages: Modest edge-holding.

Who uses it: Benchmade.

N690

What it is: N690 is a premium stainless steel produced by Bohler-Uddeholm.

Advantages: High corrosion resistance, edge retention.

Disadvantages: Can be relatively difficult to sharpen.

Who uses it: Arno Bernard Knives.

O1

What it is: O1 is a carbon steel popular with bladesmiths for hand-forged knives.

Advantages: Wear resistance, edge stability and relative toughness (although not as tough as many tool steels).

Disadvantages: Rusts relatively easily.

Who uses it: Fiddleback Forge (handmade), Mike Malosh, Oaks Bottom Forge.

Sleipner

What it is: Sleipner is a high-chromium carbon tool steel, made by Bohler-Uddeholm and used by LionSteel.

Advantages: Rust resistance, wear resistance, toughness.

Disadvantages: Can be relatively difficult to sharpen (compared to other carbon steels).

Who uses it: LionSteel.

VG-10

What it is: VG-10 is a Japanese stainless steel popular in mid-range folding and fixed-blade knives.

Advantages: Toughness, wear resistance, corrosion resistance.

Disadvantages: Can be more difficult to sharpen than carbon steels and softer stainless steels.

Who uses it: Fällkniven.